Markets

Solutions for different sectors

Discover the numerous uses of charcoal briquettes and biochar in each industry.

Agricultural and Fertilizer Industries

Briquettes in Drying Processes – used in the drying processes of grains and fertilizers, as well as coffee roasting, ensuring superior performance.

Biochar as Soil Amendment – improves soil health by increasing water retention, nutrient availability, and microbial activity.

Biochar as Fertilizer Support – benefits in nutrient management and environmental impact.

Biochar for Remediation of Contaminated Soils – captures contaminants like heavy metals and organic compounds in polluted soils, immobilizing them.

Food, Dairy, and Brewery Industries

Briquettes for Thermal Processes – used in sanitation, pasteurization, and evaporation processes to make them more efficient.

Briquettes in Steam Boilers – used in processes requiring heat and pressure, such as milk pasteurization, fermentation processes (cheese, yogurt, and curd production), cream and by-products production, brazing, beer boiling, and bottle sterilization processes, achieving higher efficiency.

Biochar as a Food Preservative – extends the shelf life of food items by managing humidity levels and inhibiting microbial proliferation.

Livestock, Poultry, and Animal Feed Industries

Briquettes in Steam Boilers – for various processes in slaughterhouses, deboning rooms, rendering plants, and sanitation, increasing efficiency.

Briquettes for Poultry Heating Processes – achieving superior efficiency.

Briquettes for Animal Feed – optimizing boilers in the pelleting process.

Biochar as a Supplement for Animal Feed – enhances the gut microbiota and immune system, while also diminishing methane discharges.

Biochar for Animal Barn Bedding – reduces contamination and ammonia emissions, controls odors, and homogenizes waste, promoting a healthier environment for animals.

Barbecue Industry

Briquettes for Grilling – offers prolonged and consistent burning, is easier to ignite, and has a lower cost than conventional charcoal.

Sanitation, Water Treatment, and Air Treatment Industries

Biochar for Water Filtration – removes pollutants and heavy metals in purification processes.

Biochar for Air Purification – removes pollutants such as volatile organic compounds and fine particles, including those in exhaust and ambient air filters.

Biochar in Waste Treatment – including sewage and industrial effluents, immobilizing or removing pollutants and pathogens.

Biochar for Odor Control – used as a natural odor control agent in various industrial and residential applications.

Construction Industry

Biochar as Partial Cement Replacement – more sustainable concrete mixes.

Biochar in Asphalt – improves durability and reduces thermal conductivity.

Biochar as Insulation Material – its low conductivity and high thermal capacity help regulate temperature and humidity.

Textile, Footwear, and Bags Industries

Briquettes for Steam Generation Boilers – enhancing efficiency in dyeing, sizing, drying, washing, and ironing processes.

Biochar as a Textile Additive – for functional clothing, aiding in moisture absorption and control, as well as regulating body temperature.

Biochar as a Deodorant and Absorbent – used in shoe insoles, bags, sports equipment, and other items where moisture and odor control are essential.

Medical, Pharmaceutical, and Cosmetic Industries

Biochar as a Cosmetic Additive – used in creams, deodorants, toothpaste, and other personal care products due to its anti-inflammatory properties and impurity absorption.

Biochar in Medical and Pharmaceutical Applications – with the potential to revolutionize various medical treatments, early studies are promising, indicating the use of biochar for improvements in detoxification, wound healing, poultices, and localized drug release. As research progresses, we can expect to see even more innovative and effective uses.

Chemical Industry

Briquettes for Steam Boilers – to optimize the efficiency of tire vulcanization processes, polymer sintering, and plastic coil production.

Biochar in Polymers, Bioplastics, and Paints – used as an additive to improve material strength and thermal properties, also making them more sustainable.

Biochar in Carbon-Based Composites – used as a precursor in the production of activated carbon fibers and carbon aerogels, which are used in various industrial applications.

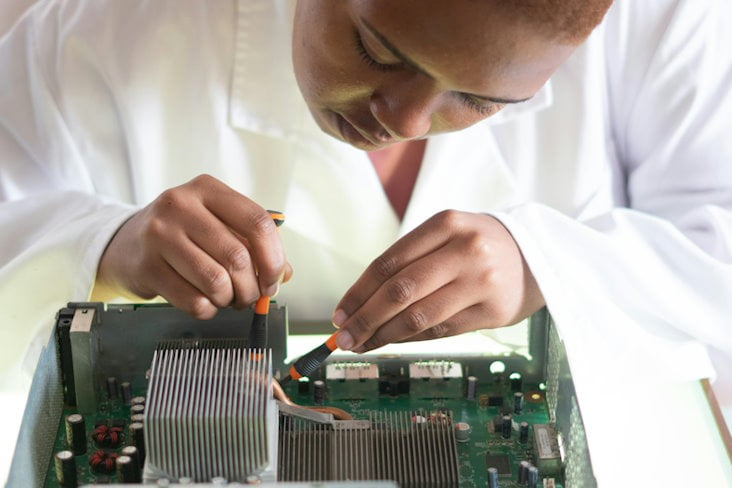

High-Tech Industry

Biochar in Batteries – used as an electrode material in batteries, particularly in lithium-ion batteries, due to its high surface area and electrical conductivity.

Biochar in High-Tech Carbons – used as a catalyst or support material in graphene production, as well as a composite material to improve the mechanical, electrical, and thermal properties of graphene.

Other Uses – biochar has garnered attention for its possible applications in cutting-edge technologies, including electronics, catalysts, and supercapacitors. Its expansive surface area and electrical conductivity position it as a fitting candidate for these advanced uses.

Metallurgical and Steel Industries

Briquettes in Steam Boilers – enhancing the efficiency of metal preparation processes such as heating baths, parts cleaning, and air heating for paint ovens and the like.

Biochar in Steel and Silicon Production – used as a reducing agent in the production of steel and silicon, providing a sustainable carbon alternative and improving energy efficiency.